Technology

Erbo Spraytec AG runs two fluidized multiprocessor production plants of the newest technology (PP-500 & MP-11; batch size ≥ 3mt). The plants are equipped with many extras and they complement each other regarding processes and materials used, so that it is possible to develop and produce a wide range of innovative powder products with very specific properties.

For R&D work, two pilot plants are on site (PP-5 & MP-1). As the pilot plants are of the same technology as the production plants, developed new processes and products can be up-scaled in house.

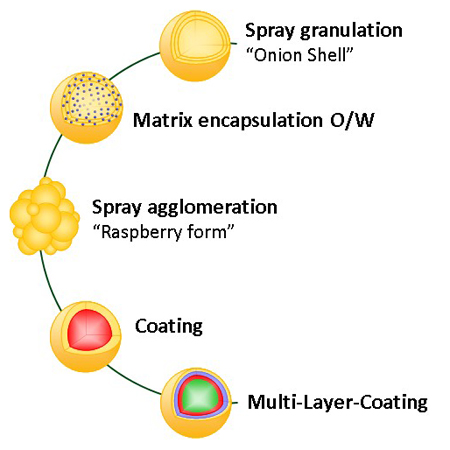

Processes

Processes with hydro soluble substances

PP-Technology (PP-500 & PP-5)

Bottom-Spray-Spouted Bed

Process air temp. +30 to +230°C

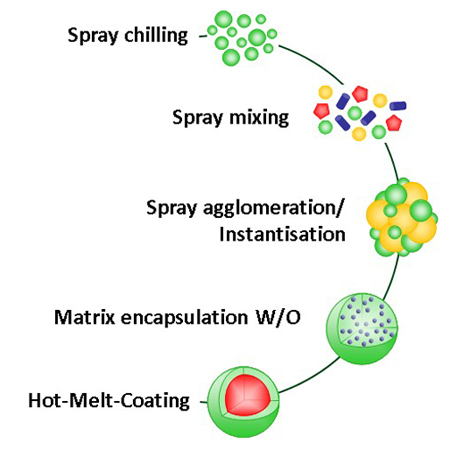

Processes with fats and lipids

MP-Technology (MP-11 & MP-1)

Top-Spray-Fluidized-Bed

Process air temp. -20 to +70°C

Processes with hydro soluble substances

- PP-Technology (PP-500 & PP-5)

- Bottom-Spray-Spouted Bed

- Process air temp.: +30 to +230°C

- Production capacity:

- Production plant: 300 - 1'100 kg/h - Size of production campaign

- Production plant: ≥ 10 tons

- Pilot plant: Small amounts (starting from 2 kg)

Processes with fats and lipids

- MP-Technology (MP-11 & MP-1)

- Top-Spray-Fluidized Bed

- Process air temp.: -20 to +70°C

- Production capacity:

- Production plant: 500 - 3'500 kg/h - Size of production campaign:

- Production plant: ≥ 10 tons

- Pilot plant: Small amounts (starting from 2 kg)

Grinding and mixing: Additional services

The grinding of coarser products and mixing of powdered components completes the spray technology offer of Erbo Spraytec AG. The two processing steps can be used as upstream and/or downstream steps for various spray products, or can also be booked as an independent service.

Grinding

- Impact mill

- Grinding of products up to a particle size of approx. 0.5 mm

- Reduction of plant material (leaves, seeds), grinding of coarse products, etc.

- Reduced products can be used as a starting product for coatings.

Mixing

- Paddle mixer

- Homogeneous mixing of dry components

- Can also be used as upstream or downstream process step for various types of encapsulation